Instrument teaches skills for automated experimentation

Lauren Smith

Jan 28, 2025

Source: John Kitchin

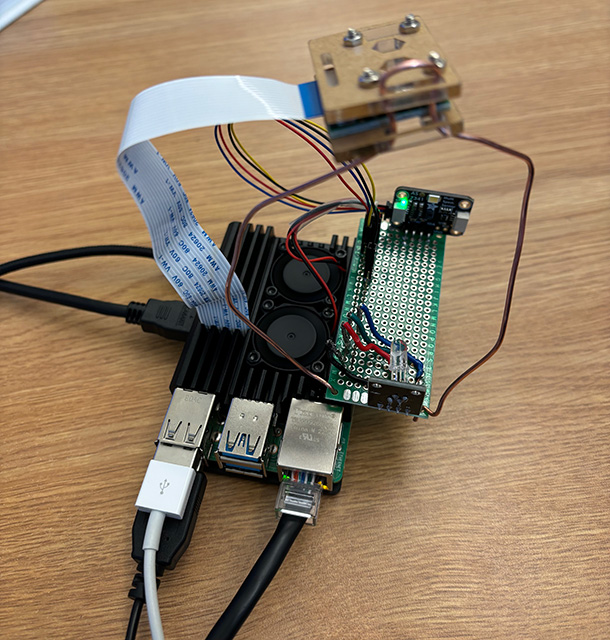

Off to the side of John Kitchin's desk, amidst papers, pens, tech, and a tea kettle, sits a handmade palm-sized device. Made of a small circuit board, a Raspberry Pi single board computer, an LED, a light sensor, and some wires, this unassuming instrument has run more than 62,000 experiments from researchers around the world.

Kitchin, a professor of chemical engineering, built the instrument to help students and researchers learn how to control a remote instrument and how to analyze the data that comes from it. It is based on a precursor instrument, published by researchers at the University of Utah as an example of the smallest self-driving lab.

Kitchin sees a huge gap between the skills needed for traditional lab work and the skills needed to work in a remotely-operated autonomous lab, also sometimes known as a cloud lab. A researcher who was able to hand-plot ten data points from ten experiments run over two weeks might, when using a cloud lab, need to analyze thousands of data points from thousands of experiments run in one day.

Cloud labs can be expensive to use, meaning that mistakes are costly. Kitchin wanted an inexpensive way to teach people the skills they need to intersect high-throughput experimentation and machine learning. "If your experiment doesn't work, where did it fail? Did you write the wrong program? Did you choose the wrong model? Was your data no good? That's a hard way to learn," says Kitchin.

His instrument, named Claude-Light, provides scaffolding for each step. "We focus first on automation. Because the data we get is roughly linear, we can make sure it does what we think it did. Then, we focus on model building," says Kitchin.

The LED on Claude-Light has a red (R), a green (G), and a blue (B) channel. The light sensor measures eight wavelengths of light and the intensity of each one. A researcher can set the R, G, and B levels independently and then measure ten outputs (the eight wavelengths, plus near infrared radiation and total light). Kitchin says the goal of the experiment is to help people learn to build models that relate the inputs to outputs. "If I have this input, what output do I expect? Or if I want this output, what input will give it to me?"

Running the RGB experiment on Claude-Light takes about a second. This means it is inexpensive for researchers to correct their mistakes and generate a new data set.

Source: John Kitchin

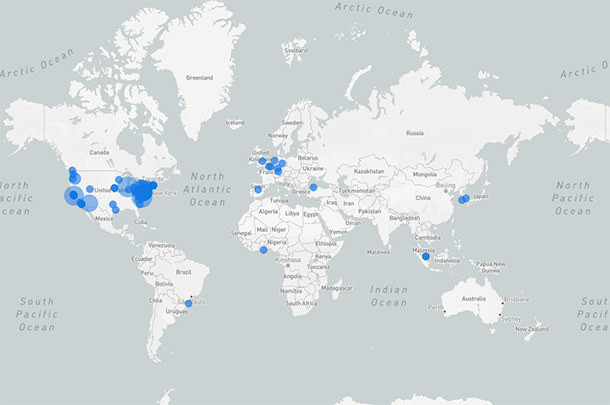

Claude-Light users come from more than 1,700 IP addresses in 13 countries around the world.

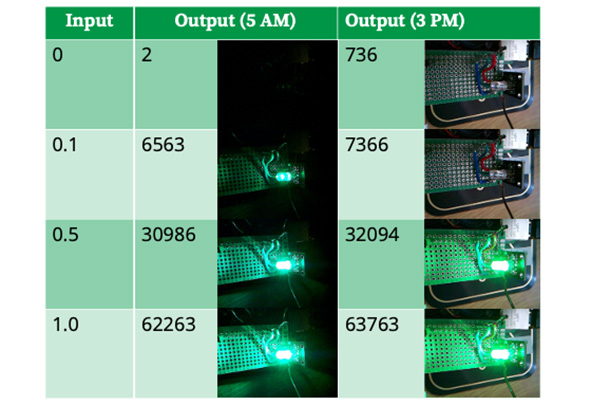

Kitchin also created an entry-level version to help students learn to visualize their data plots. Instead of three inputs and ten outputs, the Claude-Light Green Machine has one input and one output. "It's not easy to plot eight or ten numbers as a function of three. You're in this four-dimensional space at a minimum, where you can't visualize it. Claude-Light is designed to help you build your way up," says Kitchin. The way to think about fitting a model changes. "In the beginning, you fit a line. Then you can transition to fitting a polynomial, trying machine learning, or using a neural net. Those are all different models to fit exactly the same data," says Kitchin.

Students can start by changing one thing and measuring one thing, then changing one thing and measuring two, then three things. The next step is changing two things and measuring one thing. The process helps to teach reproducibility and statistics, linear regression, optimization, and design of experiments.

First-year undergraduates in Joanne Beckwith Maddock's Introduction to Chemical Engineering course used the Claude-Light Green Machine in the fall while learning the fundamentals of linear regression. Instead of using standard data and problems from textbooks, students generated their own real data. Beckwith Maddock, an assistant teaching professor of chemical engineering, instructed them to make a measurement at a different time every day for one week. Then, students calculated the standard deviation and the variance in their data. "Before, they were just calculations. Now, it's more meaningful for students to think about the causes of the variance because they had a part in the experimental design," says Beckwith Maddock.

Source: Joanne Beckwith Maddock

If the experiment is run with the same input at different times of day, the output varies widely. The light in the room is background noise in the data.

Because the Intro students made measurements at different times of day, there was different background noise. In Kitchin's design, the light sensor is open. A measurement taken when there is a lot of sunlight coming through Kitchin's office window or when the overhead light is on will be different from a measurement taken when his office is dark. Having noise in the data prompts students to account for nuisance variables.

"That's really the first step for these students to think about: what are the variables that impact my model? And how can we characterize that impact?" says Beckwith Maddock. She hopes that the Claude-Light experiment helps first-year students see how chemical engineers are part of the vanguard of automated experimentation. "Chemical engineers develop models that describe phenomena around us. Those phenomena are impacted by different variables, and chemical engineers are really good at designing experiments to get at those relationships," she says.

Kitchin says that machine learning in chemical engineering is currently limited by data. "We don't have enough data for new systems. We have to figure out how to make our experiments more data rich." With Claude-Light and other Claude instruments Kitchin is planning, researchers can start to explore what is possible when they can build and control their own instruments. "You can wait until a company makes an instrument that you can plug and play," says Kitchin. "But by the time they do that, it's not at the cutting edge of new things that haven't ever been done before."

For media inquiries, please contact Lauren Smith at lsmith2@andrew.cmu.edu.