Soy protein research provides entrepreneurial training

Lauren Smith

Nov 14, 2024

Source: Nader Rezazadeh

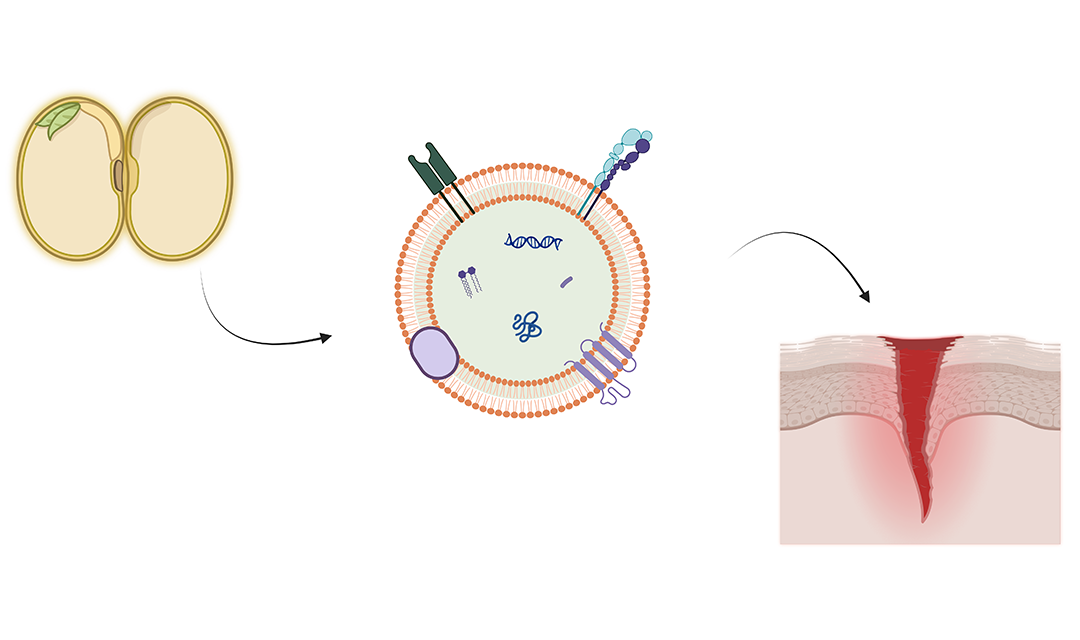

Green sources for sustainable production of bioactive signaling factors for regenerative medicine

For Nader Rezazadeh, his research is as much about people as proteins. He is working to improve the prognosis for diabetic patients with chronic wounds. In a diabetic chronic wound, the normal healing process stalls. Left untreated, they can lead to amputation, with a significant mortality rate post-operation.

Rezazadeh, a Ph.D. student in the Department of Chemical Engineering, and his advisor Phil Campbell wondered if they could change that story. "What if we could develop a novel product to change this horrific fate for the diabetic patient who is struggling with a chronic wound?" asks Rezazadeh.

They are collaborating with NeuEsse Inc., a Pennsylvania startup that is developing plant-based technology to treat chronic wounds. Rezazadeh and Campbell, a research professor in the Department of Biomedical Engineering, are using soy protein isolate to develop a novel bioactive scaffold as a wound dressing. They chose soy protein because it is a cheap, scalable, and plant-based material that reduces disease transmission risks. It also interacts with human cells to support skin cell growth, movement, and regeneration.

Source: Nader Rezazadeh

Nader Rezazadeh presenting his research poster at the 2024 Chemical Engineering Graduate Student Association (ChEGSA) Research Symposium.

Rezazadeh is co-electrospinning soy protein and therapeutic agents into nano-sized bioactive fibers for advanced wound dressings. The therapeutic components—extracellular vesicles and growth factors derived from mesenchymal stem cells—are signaling entities in the body. The wound dressing gradually releases them into the wound, where they stimulate cells to reduce inflammation and promote faster skin and tissue regeneration.

To determine the best composition of soy protein and signaling entities and to optimize the fabrication process, Rezazadeh draws on his chemical engineering training. He is studying the mechanisms of binding and releasing, including hydrophobic interactions and electrostatic interactions, along with polymer chemistry and fluid dynamics. He wants to find the optimum point for loading the highest amount of signaling entities in the soy protein fibers while achieving a prolonged and controlled release rate.

An additional challenge is that the bioactive agents need to retain their functionality when they are released into the wound. Rezazadeh must load them into the soy protein fibers without damaging their structure and functionality.

Soy protein offers another advantage as a natural polymer: it is biodegradable. Traditional wound dressings must be removed and changed, which can reinjure a chronic wound and lead to scarring. The novel biodegradable dressing that Rezazadeh and Campbell are developing with NeuEsse permits new applications directly onto previously applied material, significantly lowering the risk of pain, reinjury, and scarring during treatment.

Rezazadeh is also working on technology that could lessen pain and infection in patients with advanced-stage chronic wounds by allowing for touch-free application of wound dressings. With NeuEsse, he is developing a prototype for a portable electrospinner. The device will enable on-demand, in situ applications of the wound dressing, with the goal of speeding up the healing process.

Preliminary data is promising. Through in vitro experiments, Rezazadeh and Campbell have proved the feasibility of functionalizing soy protein isolate fibers with signaling entities and effectively releasing them into the wound area. They have also shown that the release of these components can increase the functionality of the recipient cells by around 200 percent.

Source: Nader Rezazadeh

Left: Soybeans, the natural source of soy proteins. Right: Soy protein nanofibers functionalized with stem cell-derived extracellular vesicles and growth factors, engineered as a wound dressing to accelerate healing in chronic wounds.

To make the technology more scalable for industry, the team is again turning to soy protein. They want to develop a sustainable green source for isolating extracellular vesicles as potent signaling entities. The current method of extracting them from mammalian cells is expensive and time consuming. The Campbell Lab is pioneering soy protein as a plant base from which to extract signaling entities. "Our target is to develop a sustainable way to produce not only wound dressings but also bioactive signaling entities, like extracellular vesicles, for other regenerative medicine applications," Rezazadeh says.

His research is a precursor of his career plan: to use his training in chemical engineering and biomedical engineering to develop novel products that address global healthcare challenges. Rezazadeh's goal is to found his own startup, and he chose a Ph.D. program at Carnegie Mellon University because of its support for student entrepreneurs.

Within the chemical engineering and biomedical engineering departments, Rezazadeh has found the research community to be open with advice and access to equipment. Adding his collaboration with NeuEsse, Rezazadeh says, "I think I could only get these opportunities at CMU."

For media inquiries, please contact Lauren Smith at lsmith2@andrew.cmu.edu.